Useful

Why Choose Estaparket

Full Cycle

At Esta Parket, we pride ourselves on maintaining a full production cycle that reflects our dedication to quality and sustainability. From the careful drying of raw wood to the final stages of packaging, every step in our process is meticulously managed to ensure superior craftsmanship and minimal environmental impact. This holistic approach not only allows us to maintain full control over the quality of our products but also enables us to implement eco-friendly practices at every stage. By reducing waste, optimizing resources, and prioritizing sustainable materials, we deliver products that are as environmentally responsible as they are durable and beautiful.”

This frames your full production cycle as a cornerstone of your quality and sustainability goals. Let me know if it needs further polishing!

Fixed length boards

Fixed Length Boards — ESTA Parket

Random Length — Other Factory

Unique slow wood drying process

Estaparket wood board. Perfect geometry

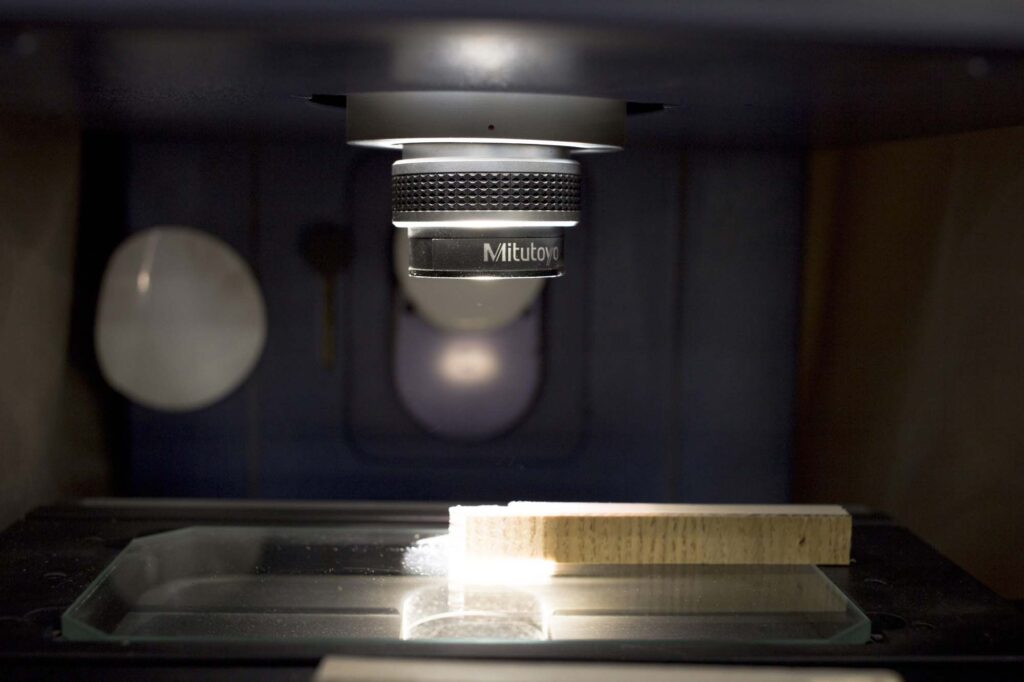

Profiling Accuracy

Our factory is equipped with the latest technically advanced machinery that increases boards profiling accuracy to 0.05 mm.

Piece of handwork in every plank. Superior quality control

At Estaparket, we take pride in our commitment to quality. Every single board we produce undergoes a meticulous manual inspection to ensure it meets our exacting standards. This hands-on approach allows us to identify and address even the smallest imperfections, guaranteeing that only the finest boards make their way to our customers. Once each board passes our rigorous quality check, it is carefully packaged to preserve its condition during transport. This dedication to detail ensures that our clients receive products that are not only beautiful but also of the highest quality and durability.

Lock System by UNILIN

Filler stained to color of design

100% Ecological. M1 certified. No added VOC/Formaldehyde

Flooring industry standards and norms have not been updated for decades and are considerably less strict than M1. Formaldehyde emissions and VOC can be very dangerous and lead to various diseases. M1 certification guarantees that emissions from Estaparket are as slow, as they are found in the trees in Nature, making Estaparket floor perfectly safe for your home.

All of our products are certified for safety standards in the following fields: FEP, CE, Class of Emission М1, Е1 Certificate, EPH Certificate, BFL.

We carefully choose materials and components, from adhesives to finishes that emit the lowest possible amount of pollutants.

According to the test results our product has one of the lowest formaldehyde emissions (4 times lower than acceptable rate) which makes it suitable even for highly allergic people. Our factory internal production standards are stricter than the requirements of the European standards.

The lacquer, oil and wood stains we use in the production, are fully organic and harmless for the environment and health. Our wood stains are water-based.

Our wood flooring is all-natural and it is a perfect choice for people with asthma or allergies. Estaparket floors are absolutely safe for your family.

Standards

All of our products are certified for safety standards in the following fields:

FEP (The European Federation of the Parquet Industry)

CE signifies that the products meet all the safety and health protection requirements of the EU.

Class of Emission М1, corresponds to Е0.

Е1 Certificate.

EPH Certificate — approves compliance with regulations on low toxic emissions level.

BFL — Highest class of fire-safety (flame-retardant construction products – Radiation intensity of 8 kW/m2)

According to the test results our product has one of the lowest formaldehyde emissions (4 times lower than acceptable rate) which makes it suitable even for highly allergic people.

Our factory internal production standards are stricter than the requirements of the European standards.

We process wood at the tightest tolerances as low as 0.05 mm

Hi-Tech

Factory is equipped with the latest technically advanced machinery supplied by unrivaled specialists in this field.

Every year we invest into innovative machining solution for wood processing.

The main advantage of our production process is that we combine manual labor with innovative equipment that ensures high quality of the end product and superb quality control. There is a hand touch on every board we produce.

Our Factory is fitted out with the latest technically advanced machinery supplied by unrivaled specialists in this field: Germany – Bürkle, Homag, Schröder, Sweden – Wood-Eye, Finland – Martek, Italy – Cefla/Sorbini, Costa. – we already have this information on website

Our five main parts of production process are gluing, profiling, manual repair, lacquering and packaging. Quality control is carefully carried out after all main stages of production.

Wide Range of Finishing Solutions

7 layers of lacquer with Anti-scratch technology ensure high wear resistance and provide our floors with stability, lasting durability.

UV-oils by KLUMPP combine the benefits of floors with a natural oil finish and UV-hardened floors. Provides a natural raw wood look and easy to clean properties.

We also offer innovative lacquering coating system that looks as natural as oiled surface and requires as little maintenance as traditional lacquered surface. The gloss level is only 5%.

Elastic & Wear-resistant lacquer

More than 300 designs. Continuous innovation.

Acknowledged by Designers as Trend Setter.

Estaparket takes pride in offering a diverse range of wood flooring designs and patterns that inspire creativity and elevate interiors.

Using a variety of wood species, such as oak, ash, merbau, and walnut, we create flooring that showcases a rich palette of colors, textures, and decorative treatments. Each design reflects our commitment to craftsmanship, innovation, and aesthetic excellence.

Our Approach

Each order is managed by a dedicated manager who oversees the process from production to the shipping of goods to the client.

Your personal manager will handle your order from the moment it is received, ensuring smooth progress every step of the way. They monitor the production process, inspect the final appearance of the product before packaging, and take an active role in quality control. Additionally, they seek the most optimal logistics solution tailored to your specific needs. Your manager is fully informed about every detail of your order, including raw materials, dimensions, and any custom requirements.

By having one person manage all aspects of your order, we ensure a seamless and convenient experience for our clients.